36" MarMac DP Dissimilar Coupler - Common Connections

36" MarMac Universal CMP DP Coupler (CMP to HDPE-HDPP-PVC)

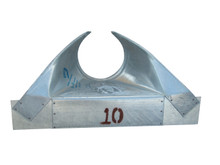

36" Metal End Section for CMP Pipe w/Rod & Lug

36" Metal End Section with Trash Rack

36" x 10' CMP Galvanized Pipe

36" x 20' CMP Galvanized Pipe

4" MarMac DP Dissimilar Coupler - Common Connections

42" CMP Dimple Coupling (2' Wide)

42" MarMac CMP Coupler (CMP to CMP) (Soil Tight)

42" MarMac CMP Coupler (CMP to CMP) (Watertight)

42" MarMac DP Dissimilar Coupler - Common Connections

42" Metal End Section with Trash Rack